Multipurpose hydraulic press for bending, stamping and straightening – PSL

Do you want different features ?

CONTACT THE SICMI EXPERTS

Our design experts are able to provide you with specific and personalized advice based on your needs and guarantee the best performance.

Your Multipurpose Hydraulic Press for Bending, Stamping, and Straightening Metals with Optimal Efficiency

(Maximum Flexibility and Precision for Your Mechanical Workshop with a Single Robust Solution)

Are you looking for a multipurpose hydraulic press that offers you the versatility to perform various metalworking operations while maintaining high standards of precision and efficiency? Our universal hydraulic press is designed to meet this need, allowing you to bend, stamp, and straighten your materials with a single reliable and high-performing machine.

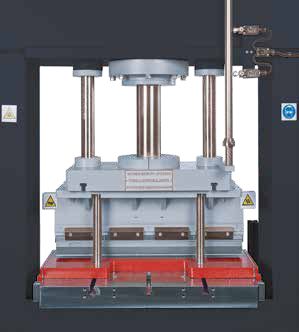

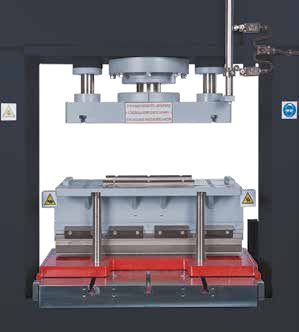

Basic Model of PSL Hydraulic Press: Specialized Efficiency for Stamping and Straightening

The basic model of the PSL hydraulic press is the ideal solution for stamping operations and precise straightening of sheet metal. Its robust structure, consisting of an upper and lower plate with T-slots and a dedicated straightening punch, ensures accurate results and simple, reliable operation.

(Primary keywords: hydraulic press for stamping, hydraulic press sheet metal straightening)

Complete Model: 3-in-1 Versatility to Optimize Your Production (Bending, Stamping, Straightening)

By choosing the complete model of the hydraulic press, you will significantly expand the capabilities of your workshop. In addition to stamping and straightening functionalities, this model includes a specific support and punch for metal bending, a V-prism, and front sheet metal supports. You will thus have a multifunctional hydraulic press capable of handling three key processes with a single investment.

(Target keywords: hydraulic press for bending, 3-function hydraulic press, hydraulic press metalworking)

What advantages does a universal hydraulic press offer for metalworking?

A universal hydraulic press like our PSL model allows you to:

- Optimize space: One machine for three different operations.

- Reduce costs: A single investment instead of three separate machines.

- Increase efficiency: Quick switching between different operations.

- Improve precision: High-quality components for impeccable results.

Customized Power and Control: Hydraulic Presses with 70, 100, and 150 Tons Capacity

Our multipurpose PSL hydraulic press is available in different power variations to perfectly adapt to your production needs: 70 tons, 100 tons, and 150 tons. Furthermore, you can choose between semi-automatic operation for direct control and automatic operation for faster and more repeatable work cycles.

How does the semi-automatic system of the hydraulic press work?

The semi-automatic system is designed for precise manual control, requiring simultaneous actuation of the lever and the start button. Integrated end-of-stroke sensors ensure accurate regulation of the cylinder movement in both directions.

What are the benefits of automatic operation in the multipurpose hydraulic press?

The automatic version of our multipurpose hydraulic press for bending, stamping, and straightening (PSL model) offers two operating modes to maximize productivity:

- Double pushbuttons: For approach speeds up to 29 mm/sec, ideal for rapid operations.

- Foot pedal: For cylinder approach speeds within 10 mm/sec, for more gradual control.

Both control systems are supplied as standard. The equipment also includes end-of-stroke sensors for the cylinder and an automatic work surface ascent system, increasing safety and efficiency. The automatic model is also equipped with a reliable Siemens PLC and precise Rexroth solenoid valves, synonymous with quality and durability over time.