Motorized hydraulic workshop press – PFF

Do you want different features ?

CONTACT THE SICMI EXPERTS

Our design experts are able to provide you with specific and personalized advice based on your needs and guarantee the best performance.

Experience Effortless Operation: Motorized Hydraulic Workshop Press with Automated Platform and Cylinder Control

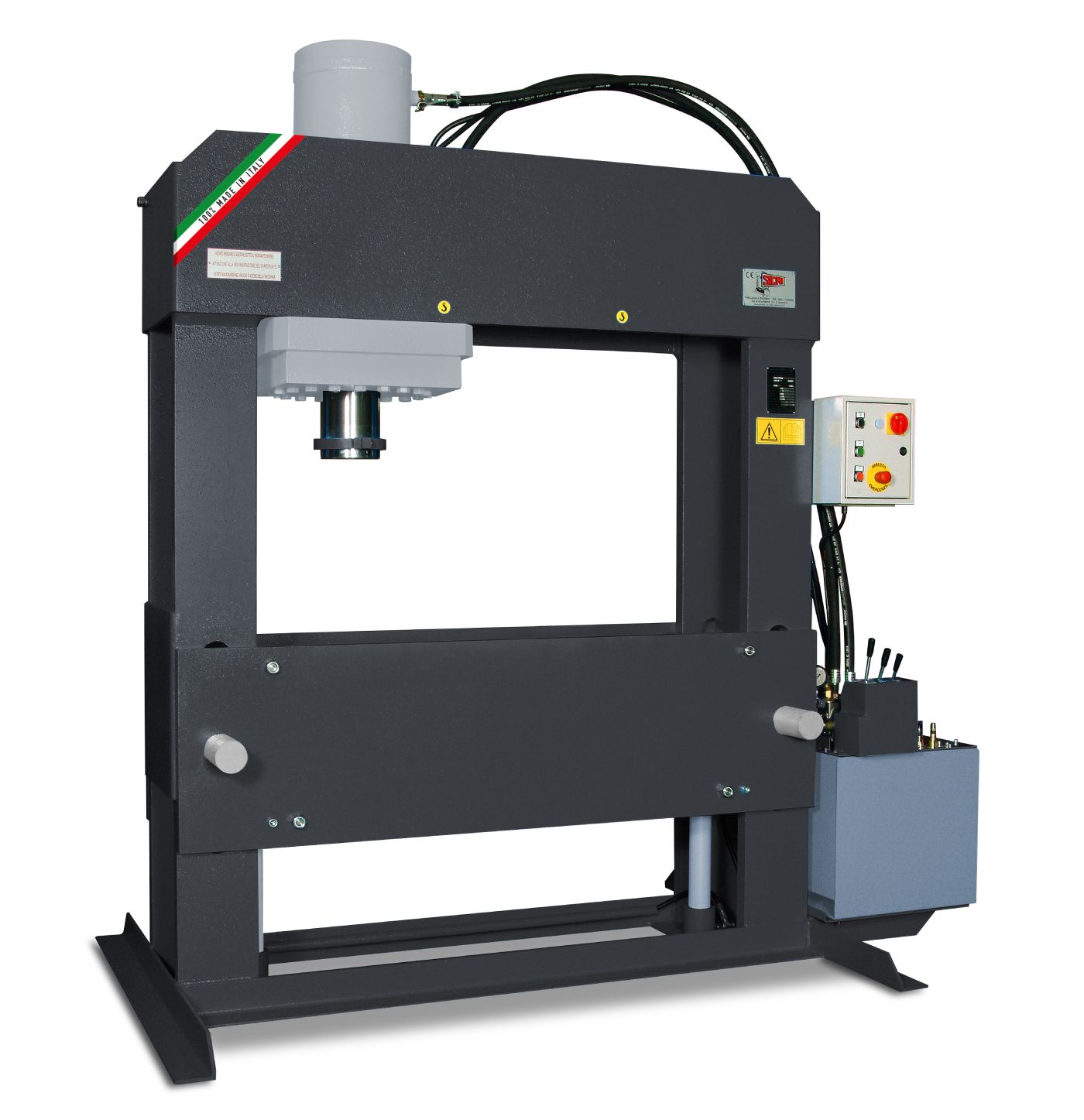

Seeking a high-performance motorized hydraulic workshop press that streamlines your operations with automated platform and cylinder movement? Our PFF series presses are expertly engineered for a wide range of tasks, from precise sheet metal straightening and deformation to efficient molding activities and various assembly and repair work. Discover the power and convenience of automated control for enhanced productivity.

Built for Demanding Environments: The Robust Strength of Our Double Column Welded Steel Frame

The double column structure of our PFF hydraulic press is constructed from fully welded milled steel, providing exceptional strength and rigidity. This robust design ensures the machine is incredibly resistant and solid, making it ideal for intensive use in busy mechanical workshops and reliable operation within demanding industrial plants.

Maximize Workflow Efficiency: Easily Handle Large Materials with a Wide Front Opening

The large front opening between the two columns of the PFF motorized hydraulic workshop press allows for the easy and unobstructed positioning of even long or wide workpieces. This practical design enhances workflow efficiency and reduces material handling time.

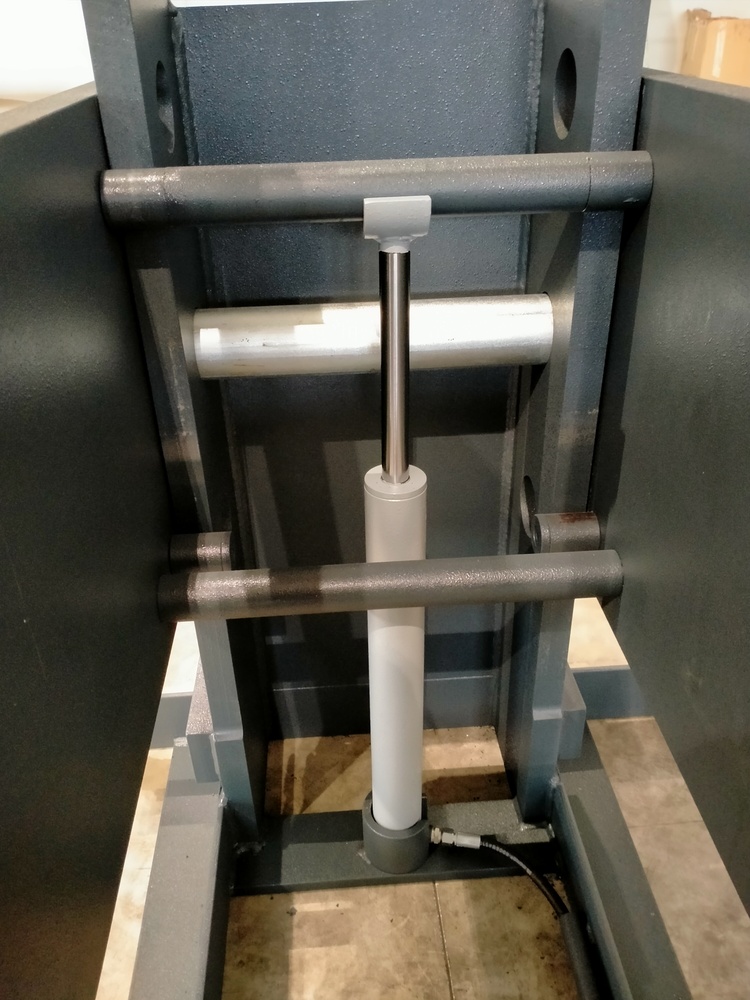

Process Materials at Optimal Height: The Convenience of a Hollow Work Surface

The PFF motorized hydraulic workshop press features a hollow work surface, allowing for the efficient processing of materials at various heights. For added stability and support, optional work support plates are available to customize the workspace to your specific needs.

Unmatched Convenience: Hydraulic Lifting of the Work Platform for Effortless Adjustment

A key feature that sets the PFF hydraulic press apart is its hydraulic lifting of the work platform. This motorized adjustment eliminates manual effort and allows for quick and precise positioning of the workpiece. The platform is securely blocked using robust steel tubes, ensuring complete stability and eliminating any unwanted movement during operation.

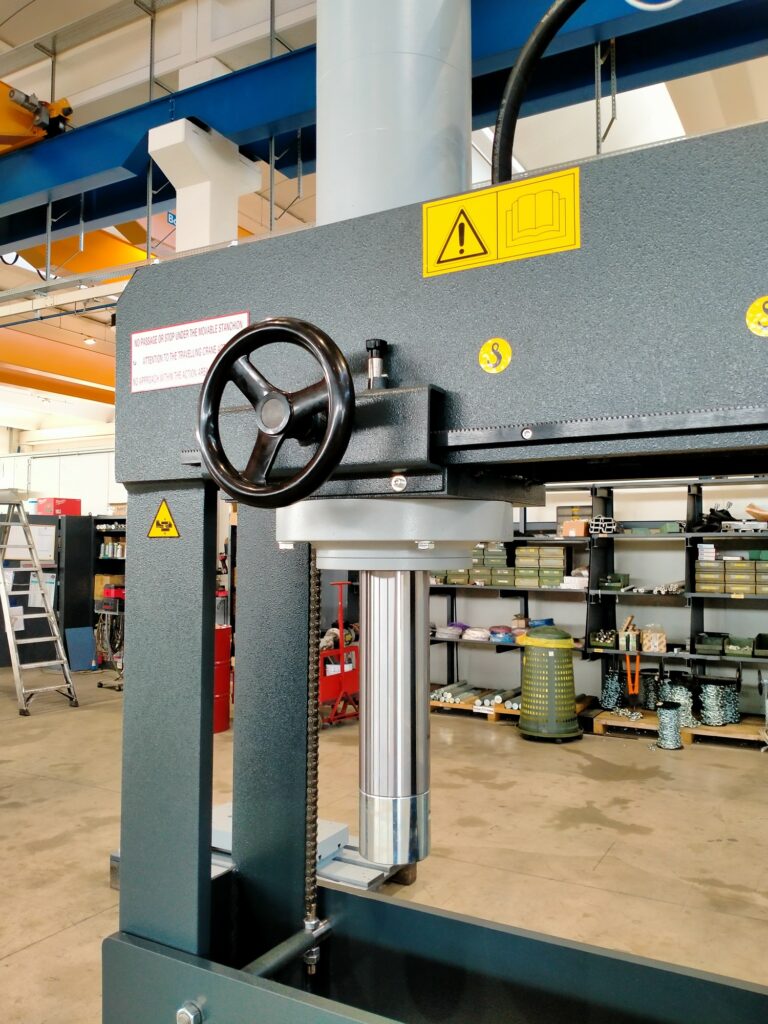

Regarding the hydraulic cylinder, you can select a fixed cylinder model or opt for the mobile cylinder version with transversal displacement. For models up to 100 tons, this lateral movement is manually controlled via a handwheel. For heavier-duty applications (150 tons and above), the PFF press features automated hydraulic movement of the cylinder, providing effortless and precise horizontal positioning for enhanced accuracy and efficiency.

Intuitive and Safe Operation: Simultaneous Lever and Button Hydraulic Controls

The hydraulic operating controls of the PFF press require the simultaneous use of the lever and button, adhering to stringent safety regulations and ensuring controlled operation.

Our PFF electro-hydraulic press is available in a comprehensive range of models, from 70 tons up to a powerful 400 tons. This extensive selection ensures you can find the perfect press with the necessary force for your specific sheet metal straightening, deformation, molding, assembly, and repair tasks.

Ready to Experience the Power and Convenience of a Motorized Hydraulic Workshop Press?

Contact us today for detailed specifications, pricing information, and expert consultation on selecting the ideal PFF series hydraulic press for your workshop or industrial facility. Our knowledgeable team can help you optimize your operations with the perfect solution.