Monoblock hydraulic workshop press – PFC

Do you want different features ?

CONTACT THE SICMI EXPERTS

Our design experts are able to provide you with specific and personalized advice based on your needs and guarantee the best performance.

The Ultimate Monoblock Hydraulic Workshop Press for Enhanced Efficiency

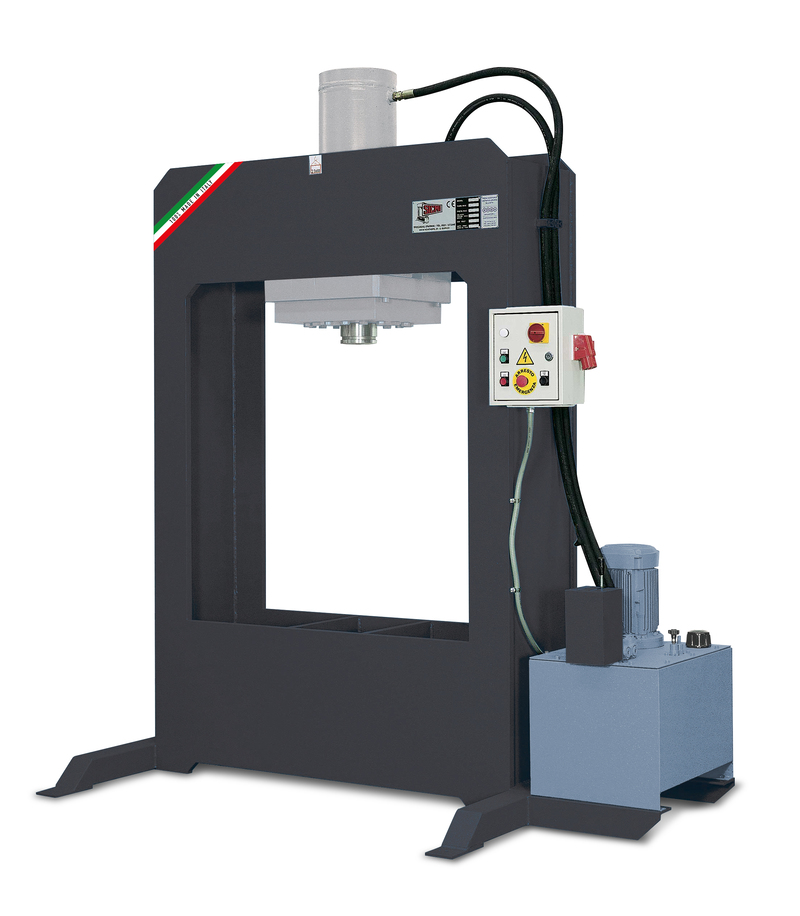

Are you seeking a powerful and exceptionally robust monoblock hydraulic workshop press designed for demanding tasks and increased operational efficiency? Our PFC series hydraulic presses, featuring the option of hydraulic transversal cylinder movement, are the ideal solution for a wide range of applications within your mechanical workshop.

Effortless Forklift Tire Dismantling and More: The Versatility of Our PFC Hydraulic Press

The PFC hydraulic press is specifically engineered as the ideal press for safely and efficiently dismantling solid forklift tires. Beyond this specialized application, its versatility extends to numerous other tasks, including precision straightening of sheet metal, the seamless mounting and dismounting of bearings, bolts, and washers, and various molding and material deformation work.

Unrivaled Strength and Stability: The Monolithic Welded Steel Frame Advantage

The double column frame of our PFC press is constructed from fully welded milled steel. This, combined with its monolithic structure, provides unrivaled solidity and exceptional resistance to even the most severe mechanical stress. For workshops demanding intensive use and industrial plants with rigorous production cycles, the PFC hydraulic press delivers unwavering reliability and long-term performance.

Maximize Your Workspace: Easy Handling of Large Workpieces with a Wide Front Opening

The generous front opening of the PFC hydraulic workshop press allows for the effortless and safe placement of even long or wide workpieces. This thoughtful design optimizes your workflow and enhances productivity, allowing you to handle a broader range of projects without limitations.

The PFC hydraulic workshop press features a hollow work surface, enabling the processing of materials at various heights for enhanced versatility. For added stability and convenience, an optional work support surface is available to suit your specific application requirements.

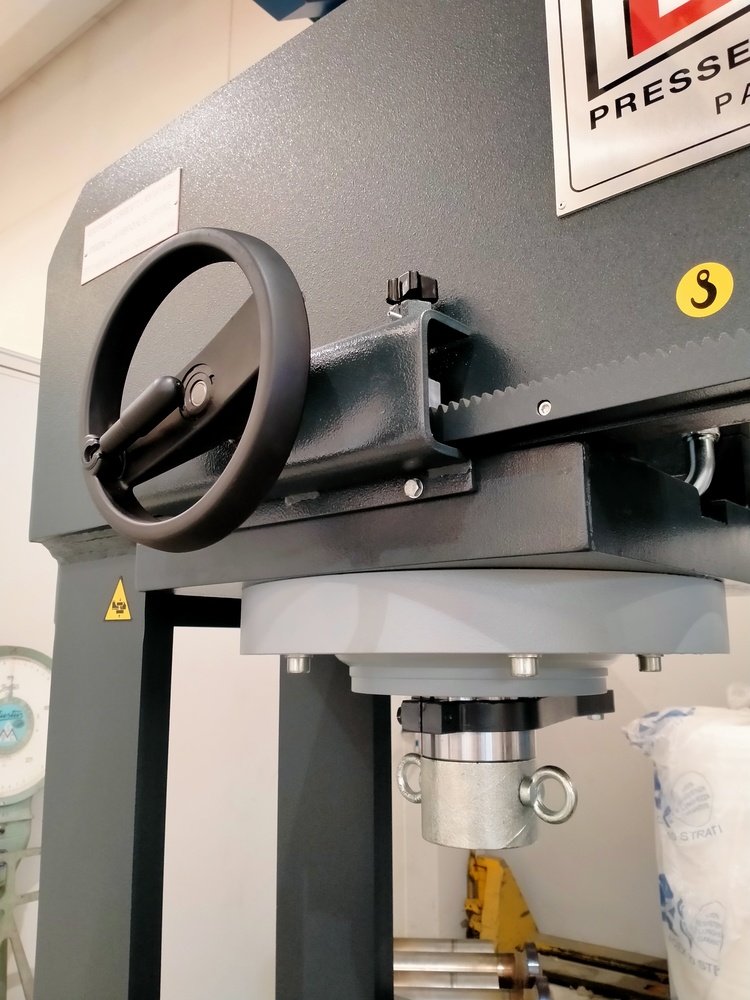

Precision and Control: Choose Your Cylinder Movement – Fixed or Electric Transversal

The powerful hydraulic cylinder of the PFC press offers a 500mm stroke and can be configured as either fixed or mobile. For models up to 100 tons, the lateral movement is manually controlled via a handwheel. For heavier-duty applications (150 tons and above), the PFC press is equipped with electric transversal cylinder movement, providing effortless and precise horizontal positioning for optimal accuracy.

Power Tailored to Your Operations: Models Ranging from 40 to 400 Tons

Our monoblock hydraulic workshop press is available in a comprehensive range of models, from 40 tons up to a substantial 400 tons. This extensive selection ensures you can find the perfect power capacity to meet the specific demands of your workshop or industrial operations.

Safety First: Compliant Operation with Simultaneous Lever and Button Control

The operation of our double column electro-hydraulic press adheres to the strictest CE safety regulations, requiring the simultaneous use of the lever and button to ensure safe and controlled operation.

Enhance Functionality with Optional Accessories:

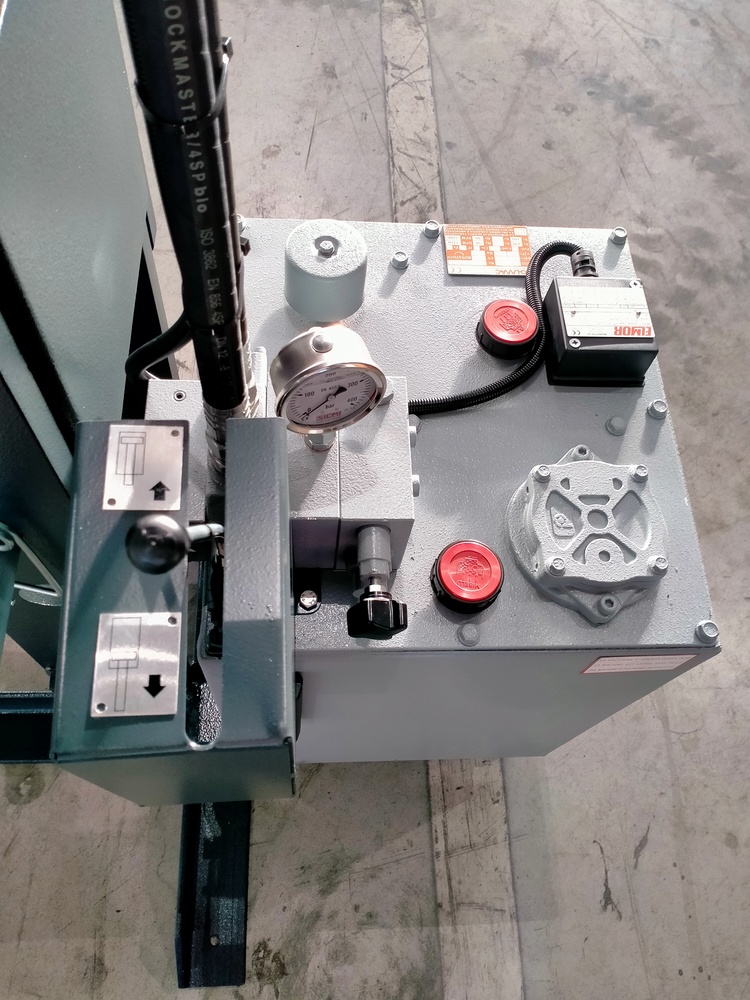

Further optimize your PFC hydraulic press with our range of optional accessories, including limit switches for automatic cylinder ascent and descent control, a pair of V-shaped prisms for specialized workholding, a support platform for added stability, and a cylinder anti-rotation system for precise alignment.

Ready to Experience the Power and Versatility of the PFC Monoblock Hydraulic Press?

Contact us today for detailed specifications, pricing information, and expert consultation. Our experienced team can help you determine the ideal model and configuration to enhance your workshop’s efficiency and productivity.