Hydraulic gantry straightening press – PMM

Do you want different features ?

CONTACT THE SICMI EXPERTS

Our design experts are able to provide you with specific and personalized advice based on your needs and guarantee the best performance.

Hydraulic Gantry Straightening Press for Metal and Carpentry Work

Are you looking for a robust and versatile solution for straightening sheet metal and tackling diverse carpentry tasks? Our hydraulic gantry straightening press, equipped with a motorized gantry and cylinder, offers unparalleled precision and efficiency. Discover how this powerful machine can streamline your operations and deliver superior results.

Unmatched Flexibility: Reach Any Point Without Repositioning

One of the standout features of our hydraulic portal straightening press is its exceptional flexibility. Thanks to the longitudinal displacement of the upper frame combined with the transversal movement of the hydraulic cylinder, you can effortlessly access any point on the workpiece. This eliminates the need for cumbersome repositioning, saving you valuable time and effort. Imagine the increased productivity you’ll achieve by focusing on the task at hand, not on adjusting the material.

Powerful Performance: Models from 150 to 600 Tons

When it comes to demanding straightening and forming applications, power is paramount. The PMM hydraulic press boasts a substantial 500mm stroke hydraulic cylinder and is available in a range of models to suit your specific needs, from 150 tons to a formidable 600 tons. Whether you’re working with delicate sheets or heavy-duty components, we have a press that delivers the force you require.

Enhanced Safety and Control: Meeting EC Regulations

Safety is our top priority. The movement of both the gantry and the cylinder (up/down, left/right) is meticulously managed through a 3-lever system that must be operated simultaneously with the control button, adhering to stringent current EC safety regulations. Furthermore, standard metal protection grids provide an additional layer of security for your operators, ensuring a safe working environment.

Customization for Your Specific Needs: Optional Accessories

We understand that every workshop has unique requirements. That’s why our PMM model hydraulic portal straightening press can be equipped with a range of optional accessories to perfectly tailor the machine to your applications. Consider these enhancements:

- Worktop totally welded to the base and bored on the surface: Provides a stable and versatile working platform.

- T-slots for locking the workpiece: Ensures secure and precise positioning of materials.

- Pendant control with 180° rotation with Rexroth solenoid valves and Siemens CPU: Offers ergonomic and reliable remote operation.

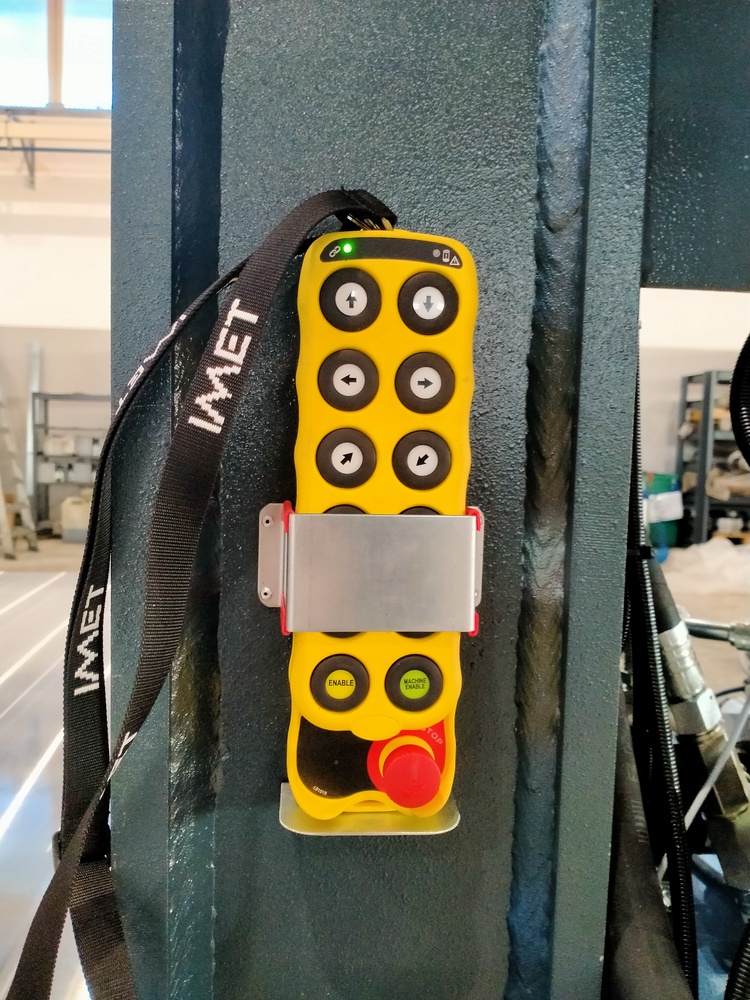

- Double button remote control with Rexroth solenoid valves and Siemens CPU: Provides an alternative remote control option for enhanced safety and control.

- Lifting cylinders inserted in the work surface: Facilitates easier loading and unloading of heavy workpieces.

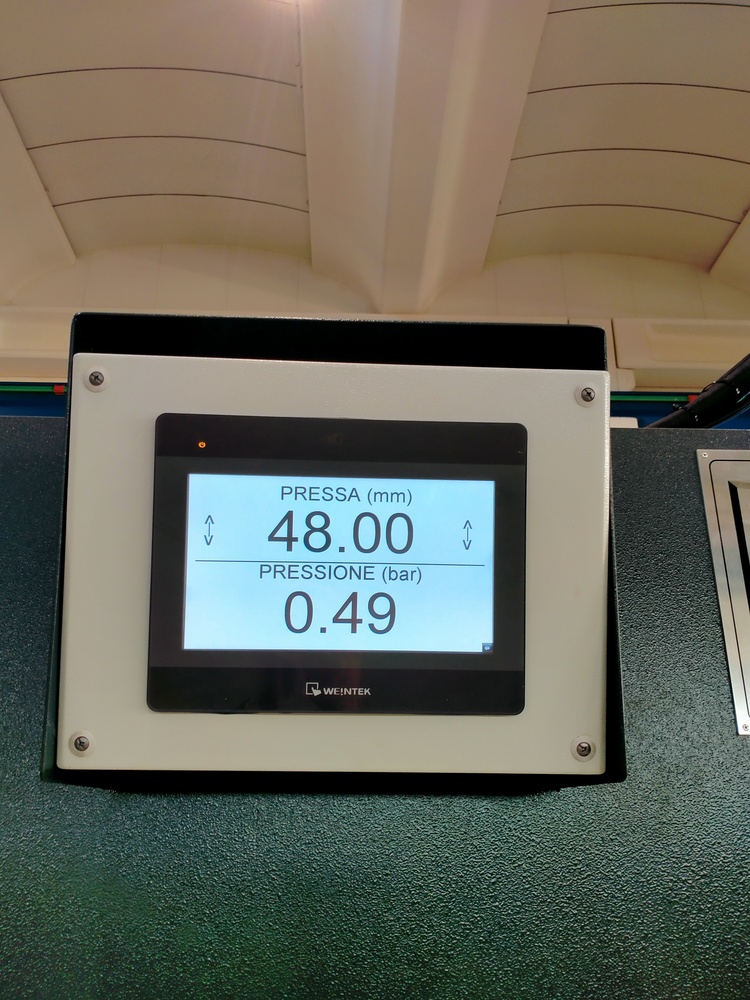

- Digital control with encoder and quota display inserted in the electrical panel: Enables precise and repeatable movements with clear visual feedback.

- Stem anti-rotation device: Ensures accurate and controlled cylinder movement.

- Air / oil cooler and decompression valve: Enhances the longevity and performance of the hydraulic system.

- LED lights: Improves visibility in the work area.