C-Frame hydraulic molding press – PCL

Do you want different features ?

CONTACT THE SICMI EXPERTS

Our design experts are able to provide you with specific and personalized advice based on your needs and guarantee the best performance.

High-Efficiency C-Frame Hydraulic Molding Press for Stamping & Sheet Metal Forming

(Maximize Your Workshop Capabilities with a Robust and Versatile C-Frame Hydraulic Molding Press)

Are you seeking a reliable and efficient C-frame hydraulic press for precise stamping operations and versatile sheet metal forming? Our PCL series press is engineered with a robust design and advanced features to enhance productivity in any workshop setting.

Robust Monolithic Frame for Unwavering Stability

The PCL press features a monolithic frame, expertly electro-welded with internal reinforcements. This construction provides exceptional stability and rigidity, ensuring consistent and accurate performance for all your metalworking tasks.

Precision Movement and Secure Tooling: Upper and Lower Tables with T-Slots

The movable upper surface of our C-frame hydraulic press is equipped with two self-lubricating guides as standard for models up to 200 tons, and four guides for higher tonnage models. This ensures smooth and precise movement during operation. It also features T-slots for secure and flexible mounting of your dies and molds.

The lower table is securely bolted to the frame and also includes T-slots, providing a stable and adaptable platform for a wide range of tooling configurations.

(Primary keywords: C-frame hydraulic press, hydraulic stamping press, sheet metal forming press)

What are the benefits of a C-frame hydraulic press for my workshop?

A C-frame hydraulic molding press like our PCL series offers several advantages for workshop applications, including:

- Accessibility: The open C-frame design allows for easy loading and unloading of workpieces from three sides.

- Versatility: Suitable for a wide range of stamping and forming operations.

- Space Efficiency: The compact design often requires less floor space compared to other press types.

- Cost-Effectiveness: Provides a balance of power and affordability for many applications.

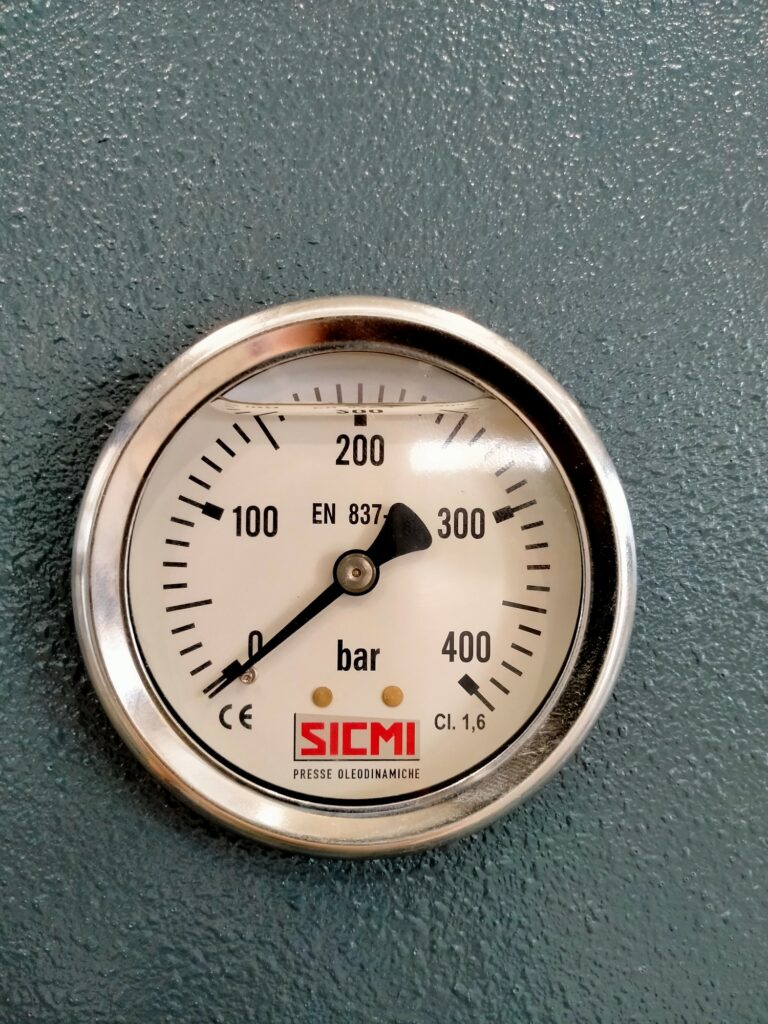

Optimized Electro-Hydraulic System for Efficient Operation

The PCL electro-hydraulic press is equipped with an optimized hydraulic system that delivers reliable power and precise control for both stamping and sheet metal deformation tasks.

Choose the Right Model for Your Needs: 40 to 300 Ton Capacity with Flexible Operation

Our PCL electro-hydraulic press is available in a range of capacities from 40 tons up to 300 tons, allowing you to select the ideal press to match your specific force requirements. We also offer both semi-automatic and automatic operation to integrate seamlessly into your production workflow.

Understanding Semi-Automatic Control

The semi-automatic version requires the operator to simultaneously use the lever and the ignition button, prioritizing safety and providing direct control over the press cycle. It is equipped with rod end stroke sensors to precisely manage the cylinder’s movement.

Enhanced Productivity with Automatic Operation

The automatic version of this C-frame hydraulic stamping press is operated via simultaneous double button control, enhancing safety and efficiency for repetitive tasks. It also features cylinder limit switches for accurate stroke control and automatic rising of the work surface, further streamlining the production process. This advanced version includes the integration of a dependable Siemens PLC and high-quality Rexroth solenoid valves for reliable and consistent performance.

User-Friendly Mobile Push-Button Control Panel

The PCL workshop hydraulic press features a convenient mobile push-button panel mounted on a pedestal. This panel houses all the main operational controls, providing easy access and ergonomic operation for your technicians.