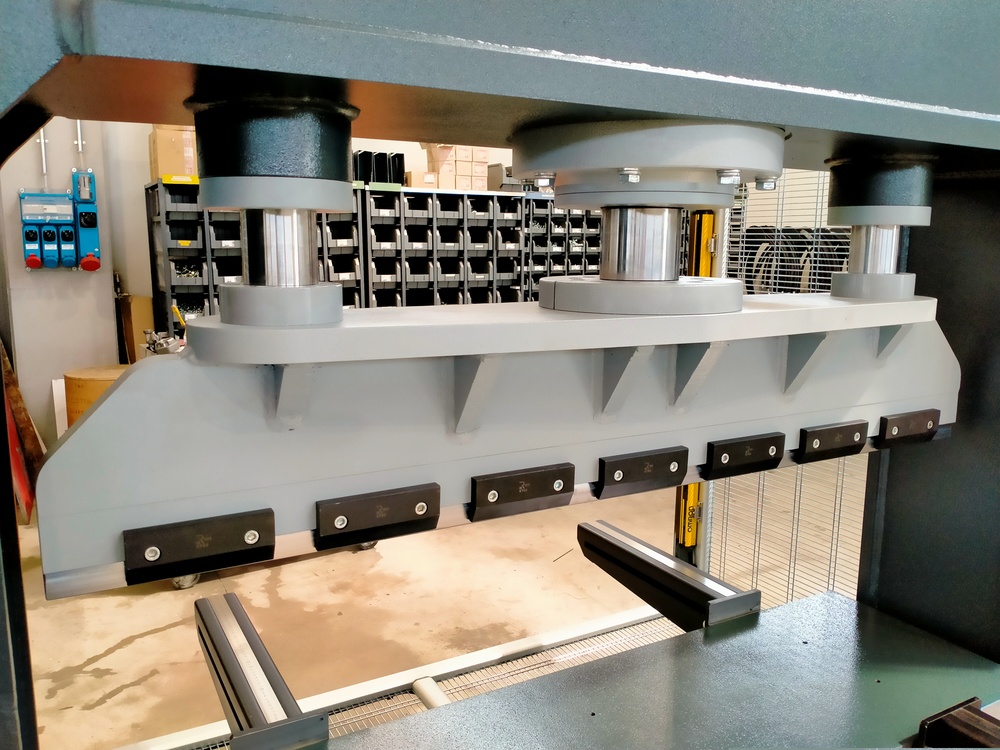

This newly produced hydraulic press bending machine is ready for shipment to a school in the Caribbean. This robust machine delivers a power of 100 tons. Its substantial distance between the columns, measuring 1550mm, allows it to bend exceptionally wide steel plates. This makes it a versatile tool for educational purposes.

The machine features a pair of front supports. These supports are equipped with a precise millimeter scale. Additionally, an adjustable stop is installed on these supports. This stop allows for micrometric locking, enabling highly accurate bends. Students can learn precise metal forming techniques with this feature.

Safety is paramount. This hydraulic press bending machine incorporates a large protective net. Immaterial barriers with photocells are installed on this net. These advanced safety features immediately halt the cylinder’s descent if an operator enters the protected area. This ensures a safe learning environment for students and instructors.

The press is controlled by a double pedal system. It also features a slow cylinder descent speed of under 10 mm/sec. According to safety regulations, this allows operators to have their hands free during the bending cycle. This enables safe and efficient manipulation of the steel plate being bent. Students can learn proper material handling techniques.

All bending working parameters are easily set via the intuitive Siemens KTP 700 Basic digital screen. This user-friendly interface allows for the storage of up to 100 different programs. Students can learn to program and execute various bending sequences, gaining valuable practical skills. This feature enhances the educational value of the machine.

Hydraulic press for bending steel – PDL