CUSTOMIZATION OF PRESSES

CUSTOM presses straightening

custom hydraulic straightening presses

This section presents some of the hydraulic straightening presses made on the basis of the specific needs of our customers.

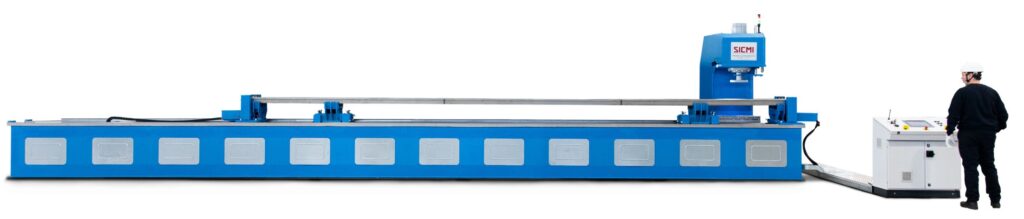

automatic hydraulic straightening press

The PCR 70 hydraulic press is engineered for automated straightening cycles of welded profiles up to 13 meters in length.

This machine features a mobile C-frame structure with motorized electric travel, providing a total stroke of 13 meters along the workpiece.

Four electrically driven mobile supports are mounted on the work platform. These supports position the metal pipes for straightening. The two outermost supports serve a dual role: supporting and elevating the metal profile. The two more central supports are solely dedicated to pipe support.

A Moog hydraulic power unit with a brushless motor is integrated into the PCR 70 hydraulic press. This efficient system uses less hydraulic oil, resulting in reduced consumption and significant energy savings.

The machine incorporates a safety perimeter with two access doors equipped with sensors and frontal photoelectric barriers.

Programming is facilitated by an electric lectern panel featuring a large display for ease of use.

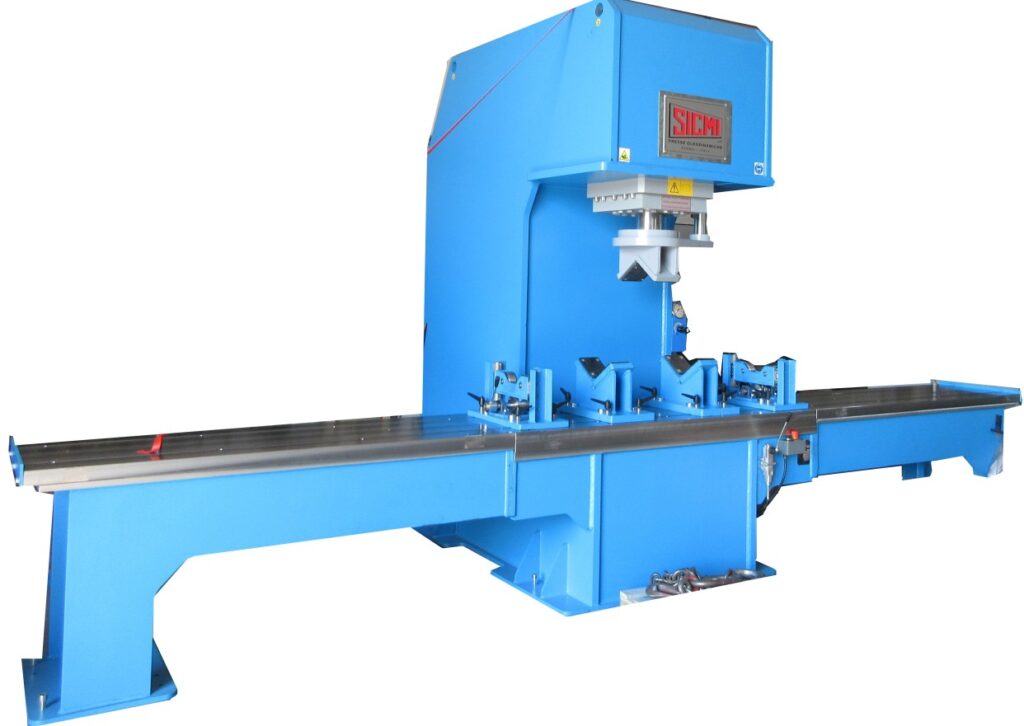

C-frame hydraulic straightening press

The PCR 150 hydraulic press enables straightening operations on pipes and round metal profiles up to 4000mm in length, utilizing a spacious work platform with side extensions.

The c-frame design simplifies the placement of the workpiece on the machine shop press.

This hydraulic press features four manually adjustable supports for positioning the metal profiles to be straightened. The two outermost supports allow for the manual lifting of the round material via a hand-operated lever, while the two innermost supports serve solely to support the tube.

The maximum force of this electro-hydraulic press is 150 tons.

hydraulic straightening press with double gantry

This hydraulic straightening press features a double gantry design for performing sheet metal flattening operations.

The PMM 300+300 hydraulic press is equipped with two pendant button control stations that operate the dual cylinders. Each cylinder generates a maximum pressure force of 300 tons. The hydraulic cylinders possess the capability of transverse movement, allowing them to reach any point on the sheet metal requiring straightening.

The expansive 3000x6000mm work platform accommodates the positioning of large metal sheets.

The PMM 300+300 electro-hydraulic press offers versatile operation. It can function with both cylinders operating simultaneously, achieving a maximum force of 600 tons for straightening thicker materials. Alternatively, the hydraulic cylinders can be used independently, effectively functioning as two separate hydraulic presses.

hydraulic press for straightening thick plates

This hydraulic press features a traveling gantry with a hydraulic motor, making it suitable for straightening thick metal sheets.

The PMM 600 hydraulic press boasts a large work platform measuring 3000x7000mm and generates a maximum pressure force of 600 tons.

The distance between the uprights is 3500mm, facilitating the easy positioning of even the largest and most cumbersome sheets.

The machine is equipped with a mobile cylinder with hydraulic actuation. A rotatable V-shaped straightening punch is installed on this cylinder. This feature allows for finding the optimal angle for deforming the sheet metal.

Ten small cylinders are integrated into the lower platform, enabling the lifting of the metal workpiece to be straightened.

hydraulic pipe flattening press

This hydraulic pipe flattening press features a mobile column with hydraulic displacement, custom-designed for the client to straighten the pipes of hydraulic cylinders used in elevators.

The PRT electro-hydraulic press is equipped with a 10-meter-long workbench. Five manually adjustable supports are installed on this bench to position the tubes for straightening. The three innermost supports serve solely to support the metal workpiece, while the two outermost supports also allow for lifting the pipe.

In this specific configuration, the PRT hydraulic press develops a maximum force of 70 tons.