OUR CUSTOMIZATIONS

CUSTOM presses STAMPING

Custom hydraulic stamping presses

This page presents some of the hydraulic presses for molding made upon request of our customers.

Hydraulic PRESS for large molds

The MST 260 hydraulic press was developed to address the requirements of industrial molding involving large-dimension molds.

This capability is facilitated by the expansive 1800x1200mm work platform, which features T-slots for securing the molds.

The upper movable structure travels along prismatic guides fitted with bronze runners. This design optimizes the parallelism of the surfaces and prevents any structural vibrations. Furthermore, the prismatic guides enable off-center operation relative to the main cylinder without compromising the machining process or causing damage to the press.

This version of the MST hydraulic press delivers a force of 260 tons and has a cylinder stroke of 500mm.

The machine is equipped with photoelectric barriers and incorporates an openable front safety net with safety sensors for the installation and removal of the working molds.

Hydraulic PRESS for molding and hydroforming of pipes

This hydraulic press was custom-built at the specific request of a client who needed to deform pipes using hydroforming, a process involving high-pressure water.

The PLC150+90 hydraulic press features a 150-ton main cylinder with a 500mm stroke and a horizontal auxiliary cylinder generating 90 tons of force with a 1000mm stroke.

The primary function of the main cylinder is to close the mold and secure the metal workpiece. Simultaneously, the horizontal cylinder deforms the tube, augmenting the shaping effects exerted by the water pressure.

The operations of the PLC150+90 electro-hydraulic press are controlled by a PLC and digital system. This allows for the customization of cylinder strokes and the adjustment of pressing durations.

For enhanced safety, the machine has been equipped with sliding front guards incorporating safety sensors.

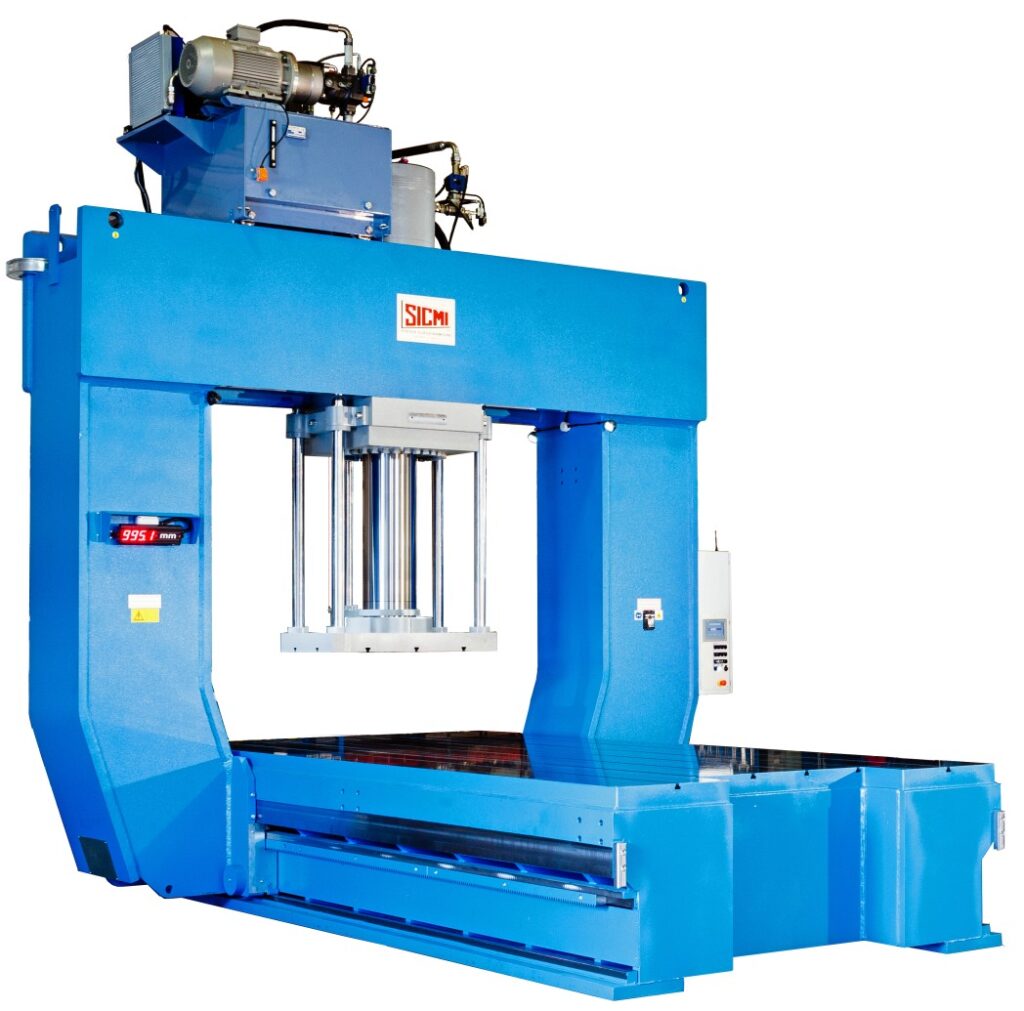

Hydraulic stamping and straightening press

The PMM 600 mechanical workshop press possesses the remarkable capability to perform both stamping and sheet metal straightening tasks.

This dual functionality is achieved through the interchangeability of the upper movable platen.

The machine features a mobile upright with hydraulic actuation. A mechanical stop is integrated into this upright to ensure precise positioning during molding operations.

The upper molding surface slides along four guides, providing enhanced stability and working accuracy.

When the hydraulic press is utilized for straightening operations, the upper molding surface is simply removed and replaced with the appropriate punch for sheet metal straightening.

This hydraulic press is equipped with a substantial working table measuring 2500x5000mm, which includes T-slots for securing the molds.

The stroke of the main cylinder is 1000mm, while the distance between the two platens is 2000mm.

4-Column Hydraulic molding press

The MQM 200 4-column hydraulic press features prismatic guides and light barriers, representing a cutting-edge machine that delivers exceptional performance and stringent safety measures.

The four stationary columns ensure unparalleled stability throughout the molding process, guaranteeing accurate and consistent outcomes. The prismatic guides enable smooth and uniform movement, eliminating any resistance and assuring flawless workmanship.

This electro-hydraulic press is equipped with light curtains, an advanced safety system capable of detecting the presence of objects or personnel. Upon detection, it immediately halts operation to safeguard operators and prevent potential accidents.

The adaptability of this press makes it perfectly suited for a wide range of molding applications, accommodating both small production runs and large-scale projects with a rapid cylinder approach speed of 125 mm/sec.